Would you also like to install an electric heating solution and still have questions? We will be happy to help you!

Electric underfloor heating in levelling compound - the universal solution for any floor covering

Maximum flexibility and safety with low installation height

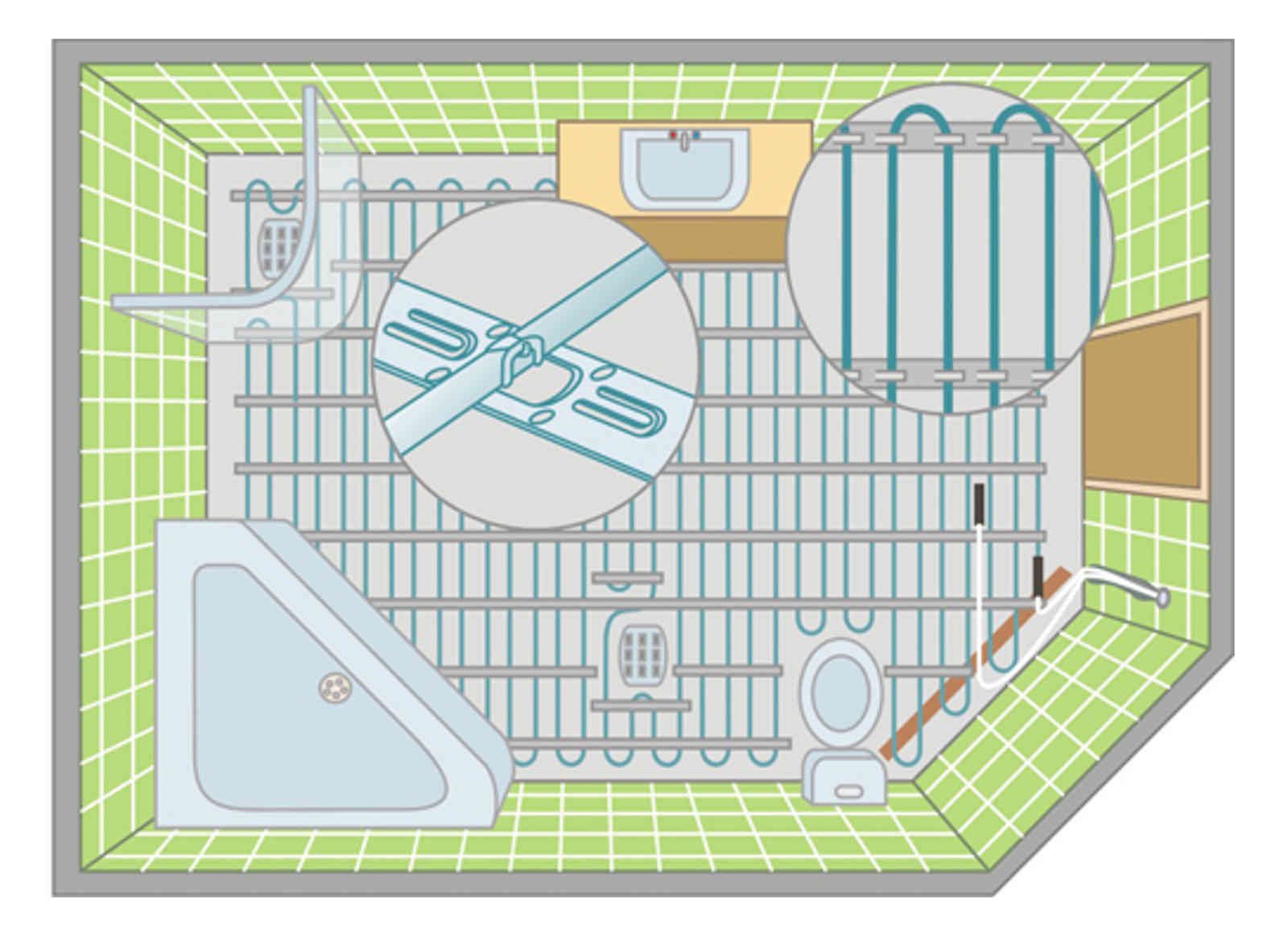

Thin-bed heating mats and heating cables enable a flexible and efficient form of electric underfloor heating - particularly suitable for renovations, retrofits and energy-efficient new builds. The systems are embedded directly in an adhesive or levelling compound and are ideal for applications where the installation height of the floor should remain as low as possible. Laying in a levelled layer has several advantages: firstly, the heating system is completely enclosed, which ensures even heat distribution and optimised heat conduction. Secondly, a stable, even surface is created - the perfect basis for almost all floor coverings, whether floating or fully bonded.

Whether tiles, vinyl, laminate or designer flooring - the full-surface embedding of the heating in a levelling compound means that there are virtually no limits to individual floor design. At the same time, the surrounding layer protects the heating conductors from mechanical stress, which has a positive effect on their longevity. These systems are also impressive in terms of safety: Thanks to the all-round protective conductor braiding and high IP protection class, they are also suitable for damp rooms such as bathrooms without any problems. They fulfil all relevant standards for wet areas and guarantee both electrical and mechanical safety.

In combination with a suitable floor structure and a precisely controllable thermostat, this creates a powerful, convenient and almost invisible heating system that can be harmoniously integrated into any room concept.

Pleasant warmth without hotspots - safe and efficient even with flexible room utilisation

A key advantage of thin-bed heating mats and heating cables embedded in levelling compound is the particularly even heat distribution. The levelling compound acts as a thermal buffer and ensures a homogeneous distribution of heat over the entire floor surface. The complete embedding of the heating conductors reduces localised heat emission and distributes it evenly to the layers above. This prevents temperature peaks and enables controlled and comprehensive heating - a noticeable advantage in everyday user comfort.

Another technical advantage is the higher thermal inertia: this means that the heat stored in the levelling compound is released slowly and evenly, preventing short-term temperature fluctuations. Even after switching off the heating, the floor remains pleasantly warm for a longer period of time.

This storage effect brings great advantages, especially in combination with a photovoltaic system. In times of ever-decreasing feed-in tariffs - down to zero feed-in tariffs with negative electricity prices - it is becoming increasingly attractive to utilise surplus electricity yourself. The equalising mass acts as a short-term heat store and allows surplus solar power to be converted into usable space heating. This increases the proportion of self-consumption and noticeably improves the cost-effectiveness of the PV system.

This installation variant is particularly interesting in rental properties or flexibly used rooms: as there is often no fixed furniture plan, it can happen that larger pieces of furniture or carpets are permanently placed on the heated surface. In such cases, the thicker layer of levelling compound prevents the formation of so-called hotspots, as the heat is dissipated evenly and cannot easily accumulate under the objects. This not only protects the technology, but also the surface coverings and increases long-term operational safety.

Simple installation of thin-bed heating mats and heating cables - even with complex floor plans

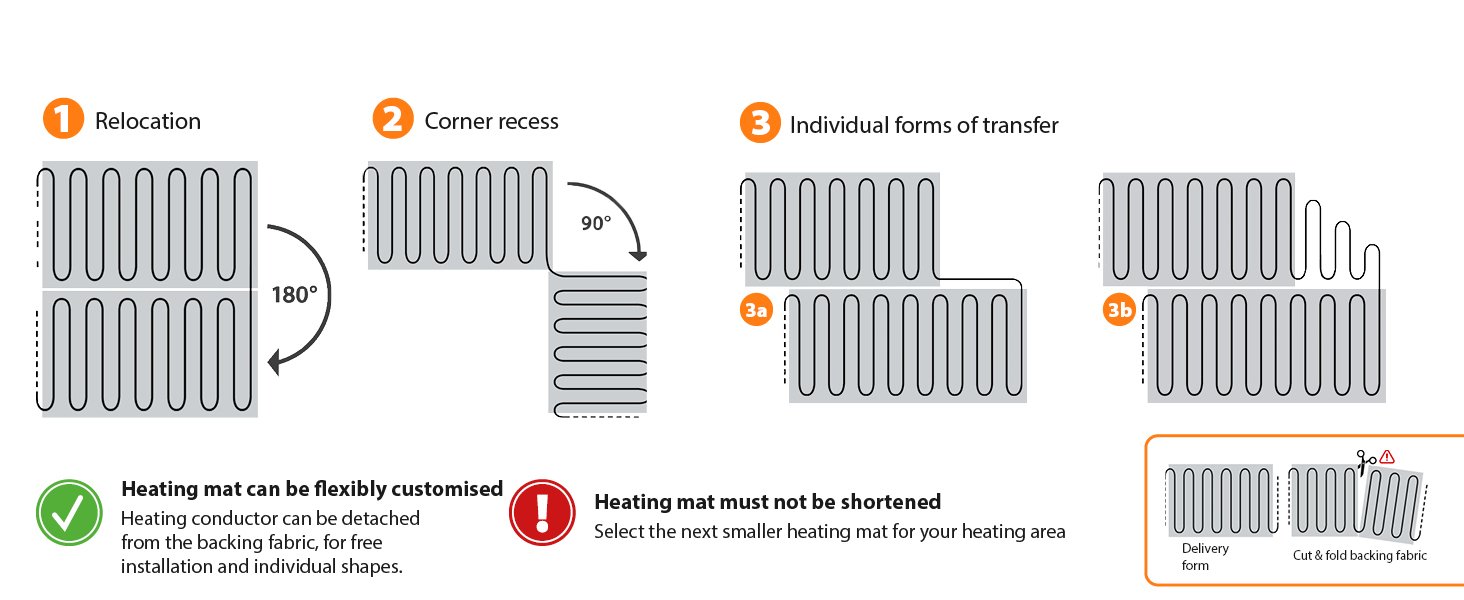

Laying thin-bed heating mats is particularly easy - even for less experienced users. The mats consist of a heating conductor that is attached to a stable glass fibre fabric in a meandering shape. This carrier fabric automatically ensures an even spacing between the cables and prevents them from slipping during installation. With a standardised width of 50 cm, the mats can be easily planned and adapted to the respective room size. Important to note: Heating mats must not be shortened. Therefore, the next smaller version should always be selected - in relation to the actual available floor area.

The backing fabric can be cut at a suitable point for customisation to the floor plan. This allows the mat to be folded over at an angle of up to 180° without damaging the heating conductor. For more complex room shapes, the heating conductor can also be partially separated from the carrier fabric and laid flexibly in order to follow the exact route required.

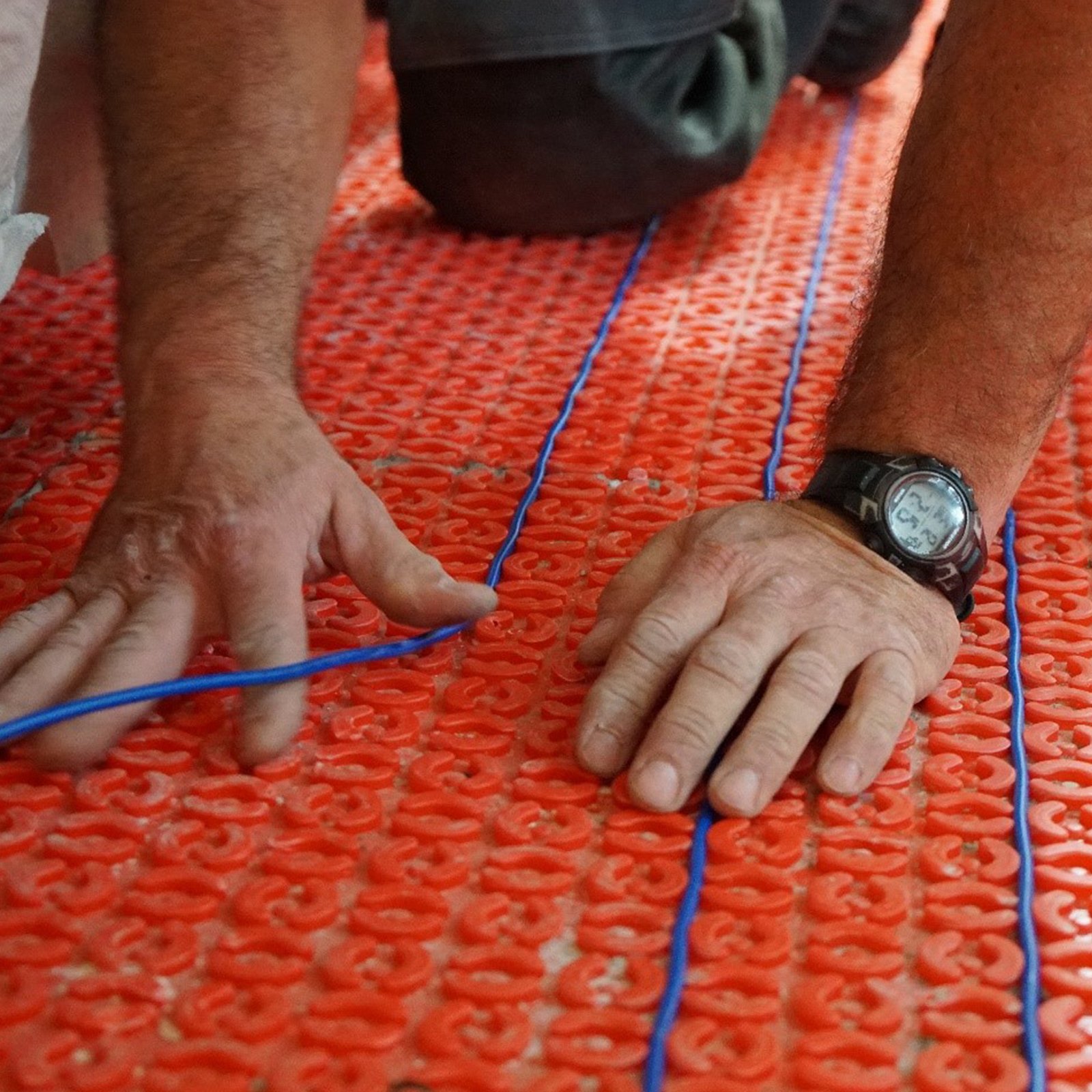

Alternatively, a pure heating cable without backing material is available for particularly demanding geometries. This enables the precise reproduction of even the most complex room shapes - such as curves, corners or steps. It is attached either using a metal mounting strip or within special decoupling mats with a studded structure. This allows reliable and full-surface heating solutions to be realised even with difficult floor plans.

Another practical advantage of modern thin-bed heating mats and heating cables is the so-called twin-conductor design. Thanks to this technology, the electrical connection is only made on one side of the heating system, which considerably simplifies installation. In contrast to older models, where both the beginning and the end of the heating cable had to be routed to the connection, today a single-sided power connection is sufficient. This not only saves time and effort during installation, but also reduces the installation height required in the transition area. This is a significant step forward in terms of convenience and ease of installation, especially in rooms with many corners or when retrofitting in existing buildings.

Decoupling and heating in one step - the solution for demanding substrates

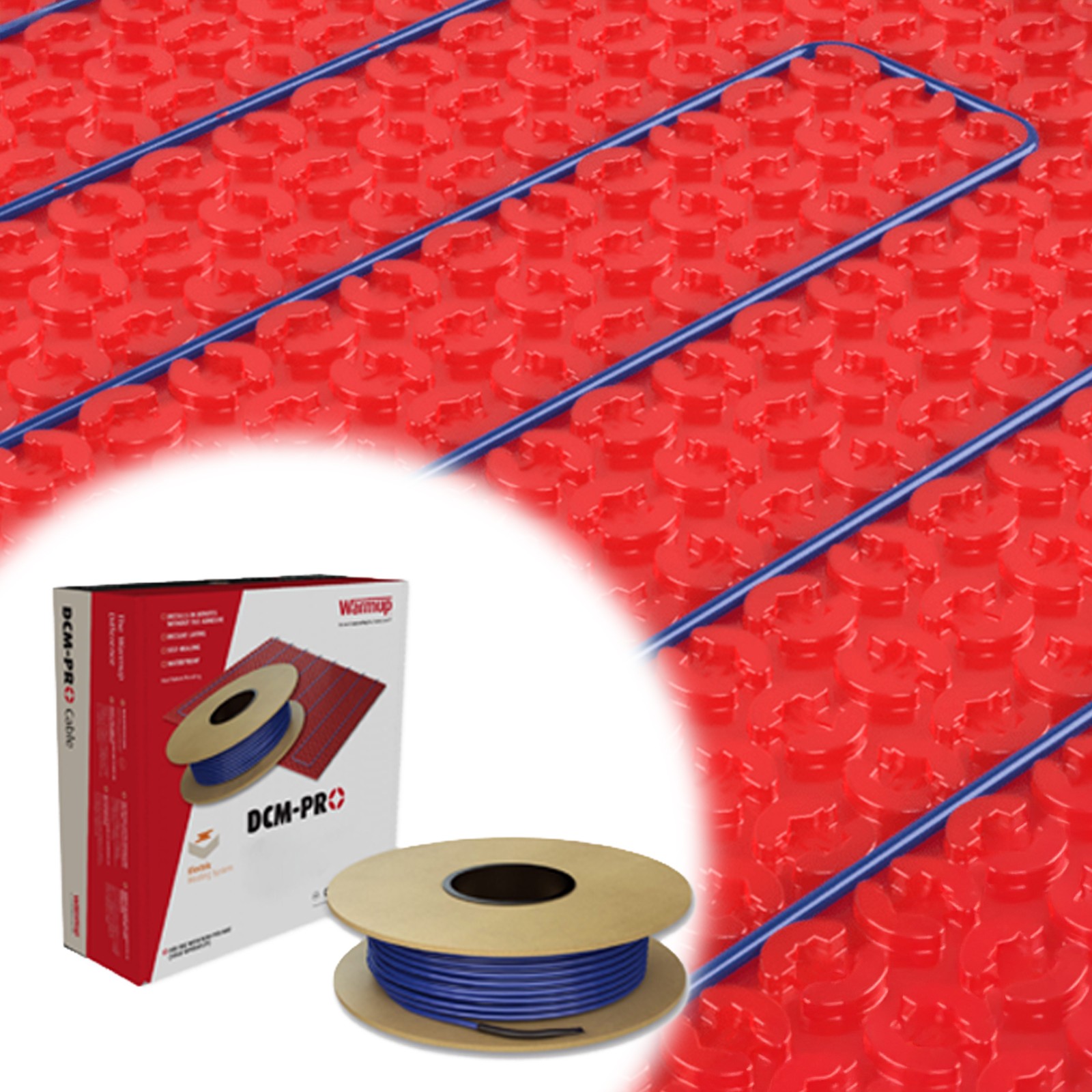

The Warmup DCM-Pro system offers a particularly clever solution for demanding substrates - a combination of electric underfloor heating and a decoupling support mat. The integrated decoupling layer provides the necessary safety, especially for renovations or critical floor structures where movement or tension in the subfloor is to be expected. It prevents mechanical stresses from being transferred from the subfloor to the floor covering and thus reliably protects against cracking - especially with sensitive coverings such as tiles or large-format slabs.

Another advantage: the decoupling mat can be flexibly cut to fit almost any room shape - ideal for angled or irregular floor plans. The associated Twin heating cable is simply pressed into the textured dimpled surface of the mat. Installation is completely tool-free. Twin technology means that only a single power connection is required, which makes installation even easier.

The total output of the system can be customised to the respective requirements. Various lengths of heating cable are available for this purpose, which is laid at a selectable loop spacing of 60, 90 or 120 mm. Depending on the cable routing, the heating output can be flexibly adjusted in the range from 130 to 230 W/m² - whether for full-surface room heating or for targeted temperature control of individual zones.

For further floor construction, the use of a fibre-reinforced levelling compound is highly recommended on critical substrates to ensure maximum stability and even load distribution. This creates a technically sophisticated, durable and universally applicable heating solution in just one work step - ideal for renovations, refurbishments or difficult substrates.

The advantages of the Warmup DCM-PRO heating system:

-

Quick installation without additional adhesive layer

The self-adhesive decoupling mat is attached directly to the existing substrate - no additional adhesive layer is required. This significantly reduces both installation time and installation costs. Thanks to the permanently elastic PU adhesive surface, the mat adheres securely, provided the substrate is dry, clean and dust-free.

-

Flexible heating output thanks to variable loop spacing

The honeycomb structure of the decoupling mat enables quick and easy installation of the heating conductor. The loop spacing can be set to either 60, 90 or 120 mm, allowing the heating output to be flexibly adjusted - depending on the installation method, output values of between 130 and 230 W/m² can be realised.

-

Wide variety of floor coverings possible

A wide variety of floor coverings such as carpet, tiles, vinyl or parquet can be used in conjunction with the DCM-PRO heating system. It is only important that these are approved for use with underfloor heating. The floor coverings are laid on the levelling compound that has been applied beforehand, which ensures an even, stable and thermally conductive surface.

-

Tool-free installation of the heating cable

The DCM-PRO heating cable is specially designed to be simply pressed into the studded structure of the decoupling mat without the need for additional tools. The cable is particularly flexible, mechanically robust and durable - ensuring maximum reliability in daily operation.

Tips from the Mi-Heat expert

Are you planning to install electric underfloor heating in levelling compound? Our support team knows the most frequently asked questions and has helpful tips at the ready - from the right installation to the right choice of material.

1) Choosing the right levelling compound

Based on our many years of experience, we generally recommend the use of a fibre-reinforced product when installing electric underfloor heating in levelling compound. This ensures significantly greater stability and optimum load distribution in the floor structure.

Depending on the manufacturer, an average of around 1.6 kg dry mass per square metre and per millimetre of layer thickness is required.

For critical subfloors - e.g. old floorboards - a fibre-reinforced levelling compound is mandatory. In such cases, a decoupling layer must also be used to reliably prevent movement in the subfloor and prevent cracking.

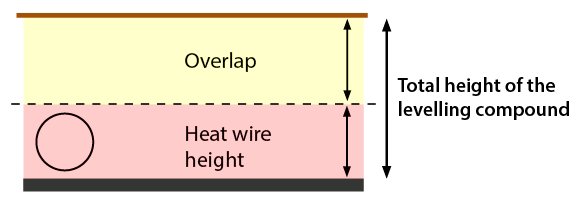

2) Plan for sufficient overlap

Sufficient overlap is crucial for the safe and long-lasting operation of heating mats and heating cables. A minimum overlap of 5 mm above the heating conductor is usually recommended - this means that an additional layer of material of at least 5 mm is added to the height of the heating cable.

We recommend that the overlap should be somewhat more generous if possible, ideally up to 10 mm if the available installation height permits. This improves heat distribution, protects the heating system from mechanical stress and increases the overall stability of the floor structure.

3) Positioning the temperature sensor correctly

In accordance with the DIN EN standard, electric underfloor heating systems must be operated with an external floor temperature sensor that limits the maximum surface temperature to 29 °C. This protects the floor covering and ensures standard-compliant operation. This protects the floor covering and ensures standard-compliant operation. Some flooring manufacturers specify an even lower maximum temperature of just 27 °C, especially for sensitive floor coverings such as vinyl or designer flooring. These specifications should always be observed and correctly stored in the thermostat.

The sensor should always be installed in an empty pipe so that it can be easily replaced in the event of a fault. Alternatively, a second sensor can also be installed as a reserve - this means that it can be easily reconnected if necessary without having to carry out time-consuming chiselling work.

Our product recommendations for you:

Deutsch

Deutsch