Overcoming problematic floors: The solution for electric underfloor heating on critical substrates

What are critical substrates—and why are they problematic?

Critical substrates are those that, due to their nature, do not provide the ideal conditions for permanent floor installation - especially in the case of tiles or jointless coverings. These include, for example, old, cracked screeds, vibrating wooden floors, or mixed constructions made of different materials. Such substrates are prone to tension, movement, or moisture problems, which can have a negative effect on the finished floor structure over time. The result: unsightly cracks, loose tiles, hollow spots, or, in the worst case, complete failure of the covering.

Overview of typical causes and risks

Cracks in the substrate are particularly treacherous, as they can continue through the covering above over time. Movable substrates such as wood or mixed surfaces consisting of screed and drywall also tend to expand differently when temperatures fluctuate – especially in combination with underfloor heating. These constant micro-stresses can become a permanent strain on the covering. Damp substrates or covering that is laid too quickly can also contribute to damage. In all these cases, we refer to critical substrates that require special structural attention.

The solution: floor decoupling as a protective layer

So-called decoupling systems are used to effectively minimize such risks. This involves laying a special separating layer, usually in the form of a decoupling mat or sheet, between the subfloor and the floor covering. This neutralizes tension, compensates for movement, and prevents existing cracks or material differences from showing through on the floor covering. At the same time, the decoupling can also serve as moisture protection or vapor pressure equalization, depending on the system. Choosing the right decoupling layer is crucial when combining a critical substrate with a durable, visually flawless floor structure.

![]() Properties

Properties

- Type: Decoupling mat

- Installation: Floating

- Suitability: Under tile adhesive or leveling compound

- Suitable for damp rooms: Limited *1

- Material thickness: 3 mm

![]() Pro

Pro

- Very low installation height and easy assembly

- Air duct system with perforation for venting residual moisture

- Integrated glass fiber reinforcement mesh

- Can be removed without leaving any residue – ideal for rental properties

![]() Contra

Contra

- no insulating properties

![]() Properties

Properties

- Type: Decoupling mat

- Installation: Self-adhesive backing

- Suitability: Under tile adhesive or leveling compound

- Suitable for damp rooms: Yes

- Material thickness: 5.5 mm

![]() Pro

Pro

- Quick and easy installation thanks to self-adhesive

backing - permanently elastic adhesive surface does not harden - Ideally suited for damp rooms thanks to

water-impermeable polypropylene material - Heating cable can be clicked directly into the stud profile

![]() Contra

Contra

- No insulating properties

- Not easily dismantled

![]() Properties

Properties

- Type: Insulation and decoupling mat

- Installation: Glued

- Suitability: Under tile adhesive or leveling compound

- Suitable for damp rooms: Limited *1

- Material thickness: 6 mm

![]() Pro

Pro

- Combines insulating layer and

crack-resistant decoupling in one product - Integrated aluminum layer for fast

and even heat distribution - Reduces energy consumption by up to 12%,

saving you money

![]() Contra

Contra

- not easily dismantled

*1 Suitable for damp rooms only in combination with sealing slurry or similar products.

*1 Suitable for damp rooms only in combination with sealing slurry or similar products.

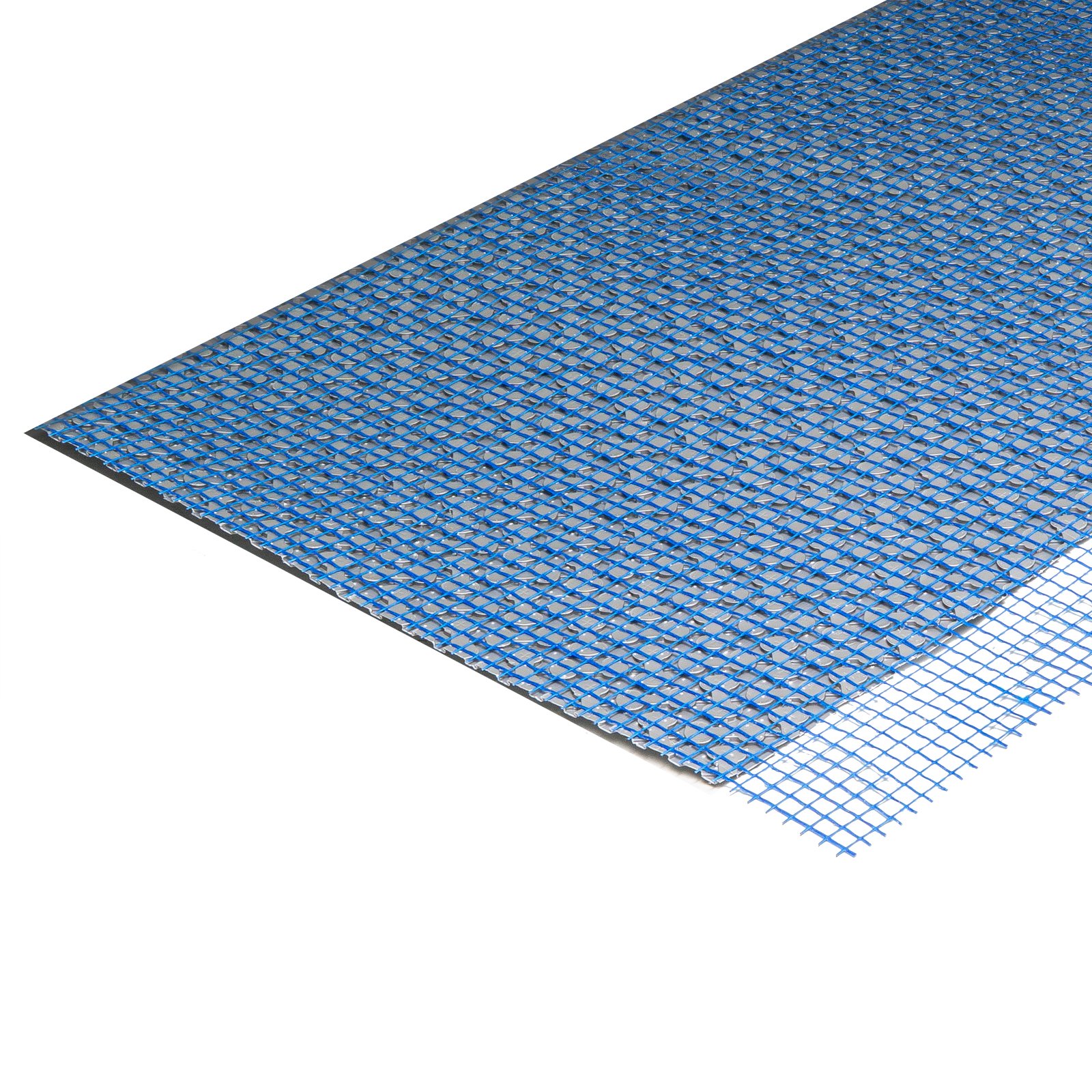

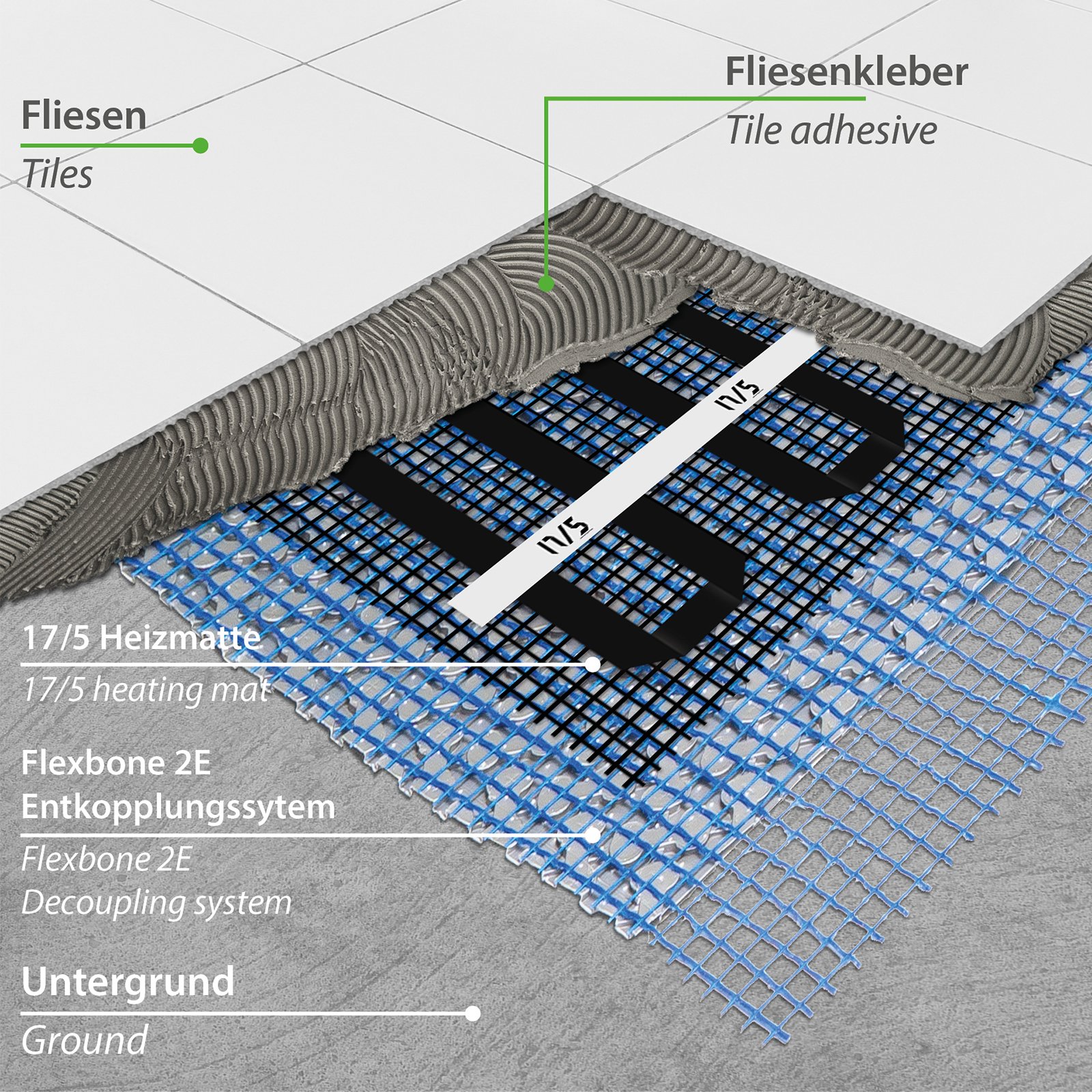

Floor construction with Flexbone-2E decoupling mat

The FLEXBONE-2E decoupling mat is a special solution for floating installation on critical or problematic substrates. Unlike traditional decoupling systems, it is not bonded to the screed or subfloor, but laid loosely. This has several advantages: Firstly, the existing substrate is not permanently altered, and secondly, the mat can be completely removed without leaving any residue if necessary. This is a decisive argument, especially in rental properties or when renovating existing buildings, because floor coverings can be removed easily without risking damage to the substrate.

The functional principle of FLEXBONE-2E is based on its characteristic air channel system. The crosswise arranged channels with targeted perforations enable controlled ventilation of the floor. This allows residual moisture from new screeds or rising moisture from critical substrates to escape without affecting the top layer. At the same time, the geometry of the mat ensures effective decoupling. Movements in the substrate are absorbed and not transferred to the tile covering. The risk of cracks or detachment is significantly reduced.

Another key component is the integrated glass fiber reinforcement mesh. It gives the mat a high degree of stability and ensures that the tile adhesive or leveling compound adheres reliably to the system. This creates a continuous base layer that distributes loads evenly and ensures a durable bond between the substrate and the covering.

Installation is practical and time-saving: the mat strips are first cut to size and laid as a floating floor. The tile adhesive is then applied directly, and the tiles are laid. Alternatively, a self-leveling compound can be used if a flat surface is required or if additional components such as electric underfloor heating are to be integrated. The system is particularly suitable for thin-bed heating mats or heating fleeces with a low installation height. These are laid directly into the adhesive layer or completely covered with leveling compound. It is crucial that the heating conductors are covered with a layer of at least 5 mm to ensure both stable load distribution and permanent protection of the heating components.

FLEXBONE-2E is also suitable for damp rooms such as bathrooms or kitchens, but with restrictions. However, it is important that additional moisture protection is installed in such areas – for example, mineral sealing slurry, liquid foil, or comparable sealing systems. Only this combination makes the construction permanently water-resistant and allows it to be used in areas where splashing or cleaning water is to be expected. For permanent wet areas or heavily used zones, however, the use of special sealing and composite systems is recommended.

In practice, this means that IndorTec FLEXBONE-2E can be used to quickly make even difficult substrates usable. A new screed that still contains residual moisture can be covered just as easily as an old floor that does not allow for secure bonding. The floating construction and decoupling effect reliably absorb movements. At the same time, you remain flexible for the future – if you need to change the covering, the mat and top layer can be removed and a new system installed.

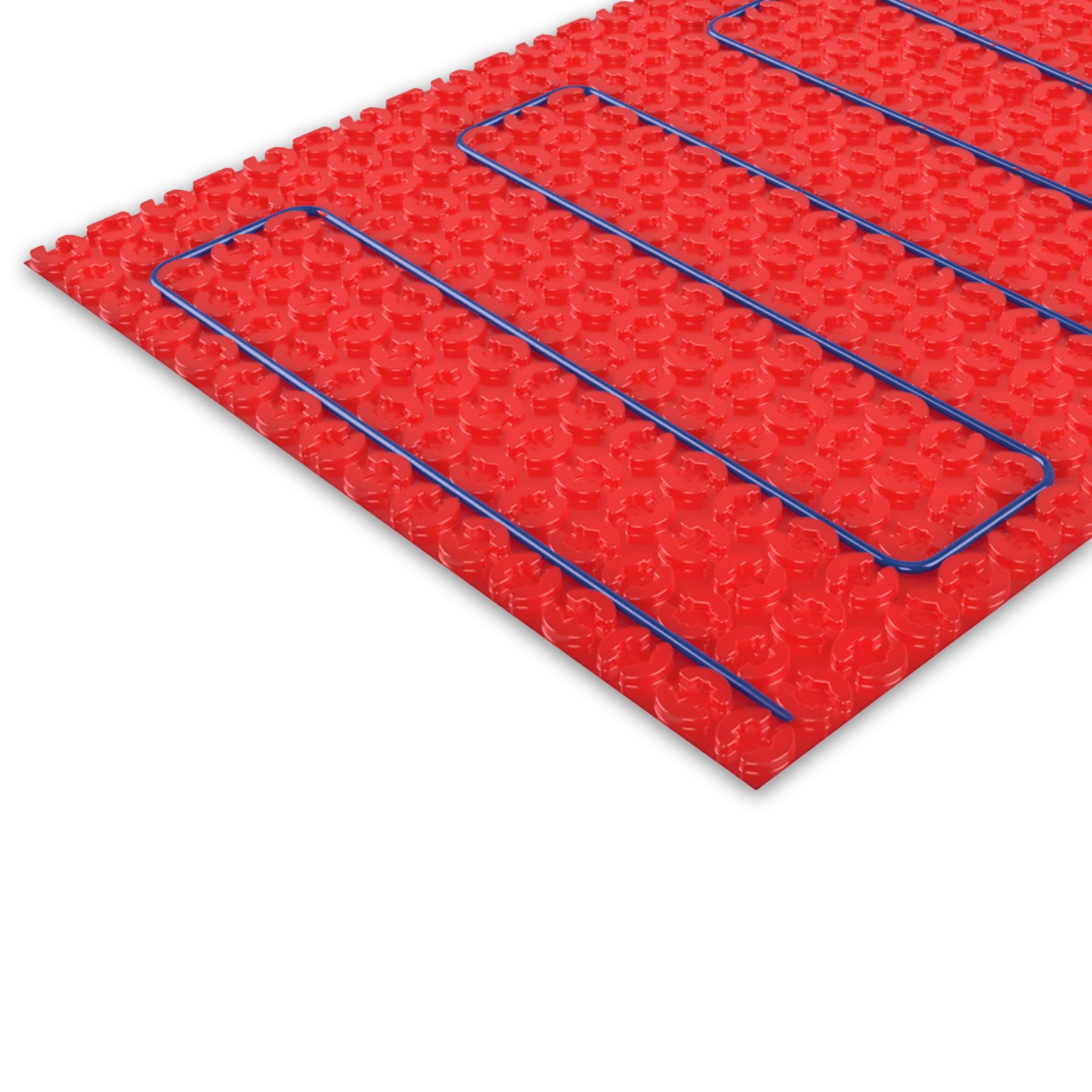

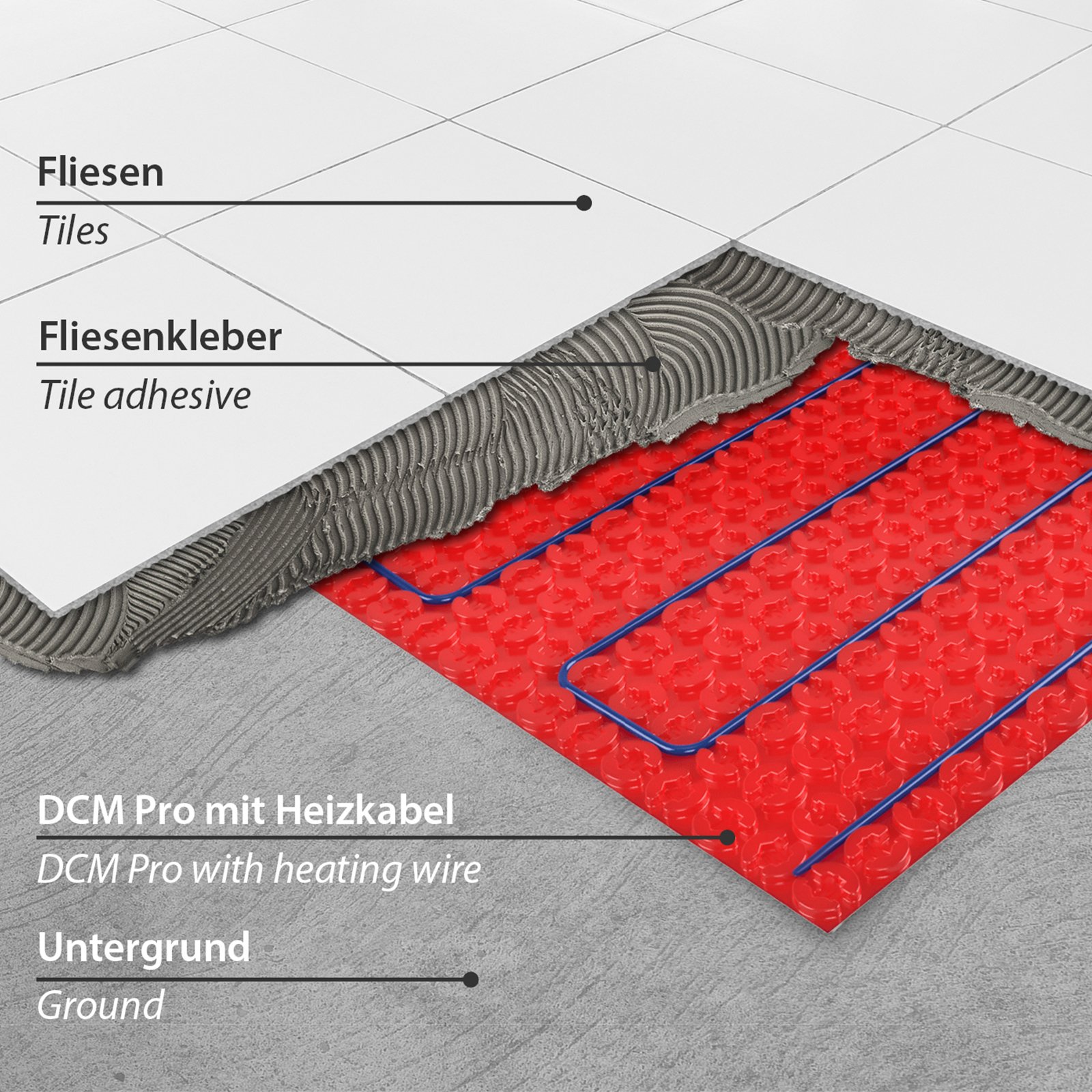

Floor construction with the DCM-Pro system

The DCM-PRO decoupling mat is a modern system that has been specially developed for the safe installation of ceramic coverings in combination with electric underfloor heating systems. Unlike floating mats, it is fixed directly to the prepared substrate with a self-adhesive backing. This permanently elastic adhesive surface does not harden, but remains permanently flexible – this allows tensions between the substrate and the top covering to be reliably absorbed without causing cracks or detachment. At the same time, the self-adhesive backing saves valuable working time, as no additional primers or adhesive layers are required. The strips are cut to size, laid down, pressed on and can be walked on immediately.

The material consists of water-impermeable polypropylene. This makes the system suitable for use in damp rooms without restriction and can also be used in bathrooms, kitchens or utility rooms. In combination with a standard-compliant waterproofing, a safe and permanently water-resistant floor structure is created. With a thickness of 5.5 mm, the installation height is slightly higher than classic thin-layer systems, but offers a very robust base for the subsequent covering.

A special feature is the mat's studded profile: it allows the heating conductors of the electric underfloor heating system to be clicked directly into the structure. These are fixed in place by the studs and can be laid quickly and easily – without additional fastening materials. After installation, the heating conductors are covered with tile adhesive or levelling compound. It is important to ensure a minimum coverage of 5 mm so that the heating wires are permanently protected and the heat can be evenly distributed throughout the floor.

The DCM-PRO system also offers flexibility in terms of heating output: the spacing between the heating cables can be individually selected at 6 cm, 9 cm or 12 cm. This allows the heating output of the electric underfloor heating to be specifically adapted to the room situation – from approx. 230 W/m² for narrow installation spacing to 130 W/m² for larger spacing. This means that both comfortable additional heating in the bathroom and powerful main heating can be implemented.

After inserting the heating conductor and covering it with adhesive or filler, the surface is immediately ready for covering. Tiles or natural stone slabs can be laid directly, or alternatively, a flat filler can be applied before another covering is installed. The permanently elastic structure ensures reliable decoupling in all cases and significantly reduces the risk of stress cracks.

In practice, the DCM-PRO mat is suitable for both new buildings and renovations. It can be used on screed, concrete or even wooden substrates. Thanks to the combination of secure decoupling, quick installation and the direct integration of heating conductors, the system offers a particularly efficient solution for modern underfloor heating in wet rooms and living areas.

The DCM-PRO decoupling mat is therefore a well-designed complete solution: it combines easy handling with high functional reliability, enables individually adjustable heating output and creates a resilient substrate for ceramic coverings – ideal wherever warmth, comfort and durability are required.

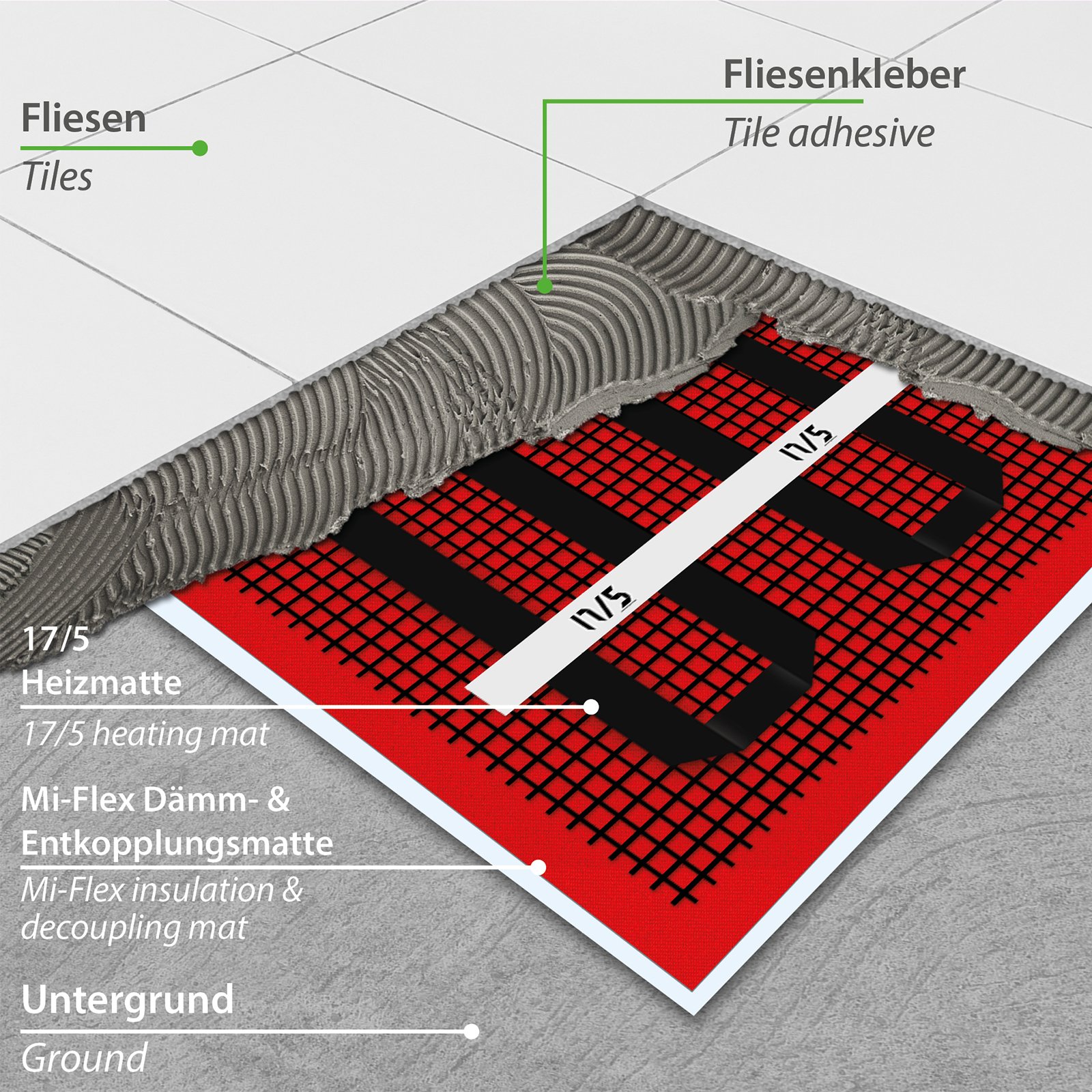

Floor construction with Mi-Flex decoupling mat

The Mi-Flex insulation and decoupling mat is a combination product that combines several functions in one system: it provides thermal insulation, reduces tension between the substrate and the top covering, and supports even heat distribution. This makes it an ideal basis for the use of electric underfloor heating in combination with ceramic coverings or levelling compounds.

Unlike floating mats, Mi-Flex is bonded directly to the substrate. Depending on the nature of the floor, a suitable floor covering or tile adhesive is used. The firm bond creates a stable structure that functions reliably even under higher loads. The material thickness of around 6 mm contributes only moderately to the overall height, but at the same time provides effective thermal insulation and an additional decoupling layer.

A special feature is the integrated aluminium layer within the mat. This ensures rapid and even heat distribution across the entire floor area. In combination with an electric thin-bed heating mat or a thin heating fleece, which can be laid directly on the Mi-Flex, this results in a particularly efficient heating system. The aluminium layer not only supports even temperature distribution, but also reduces energy consumption by up to 12% – an advantage that is particularly noticeable with regular heating.

The layer structure is practical and simple: first, the Mi-Flex insulation and decoupling mat is glued to the entire surface of the substrate. This is followed by the installation of the heating elements – either thin-bed heating mats or heating fleece. In the next step, the construction is covered with a layer of tile adhesive, into which tiles or natural stone slabs can be laid directly. Alternatively, a levelling compound can be used to create a flat surface if other floor coverings are planned. In any case, it is crucial that the heating conductors are securely embedded and completely covered so that they remain permanently protected and the heat is optimally transferred to the floor structure.

The Mi-Flex mat is also suitable for damp rooms, but only to a limited extent. It is important here that additional moisture protection is installed – for example, in the form of sealing slurries or liquid-applied waterproofing systems. Without this additional waterproofing, the mat should not be used in areas that are permanently exposed to splashing or cleaning water.

In practice, Mi-Flex insulation and decoupling mats offer a sophisticated combination of function and efficiency. They insulate against cold from the subfloor, decouple the top layer from movements in the screed, distribute heat evenly and increase the energy efficiency of the entire system. This makes it particularly interesting where comfort, economy and durability are equally important – whether in new buildings or renovations.

Tips from the Mi-Heat expert

Are you planning to install electric underfloor heating on a challenging substrate? Our support team is familiar with the most common questions and has helpful tips at the ready – from correct installation to choosing the right materials.

1) Selecting the correct levelling compound or adhesive

Based on our many years of experience, we generally recommend using a fibre-reinforced levelling compound or a flexible tile adhesive when installing electric underfloor heating. Both options ensure significantly higher stability, reliable embedding of the heating conductors and optimum load distribution in the floor structure.

Depending on the manufacturer, levelling compounds require an average of around 1.6 kg of dry material per square metre and per millimetre of layer thickness. The consumption of tile adhesive with 8 mm notches is usually around 2.8 kg/m².

2) Allow for sufficient coverage

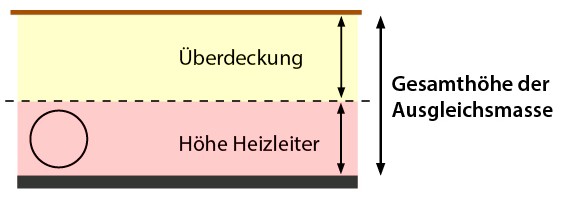

The right coverage is crucial for the safe and long-lasting operation of heating mats and heating cables. As a guideline, a minimum coverage of 5 mm above the heating conductor is required – this means that an additional layer of at least 5 mm must always be added to the construction height of the heating cable.

If the installation height allows, the covering should be slightly more generous. This improves heat distribution, protects the heating system from mechanical stress and increases the stability of the floor structure.

3) Position the temperature sensor correctly

In accordance with DIN EN, electric underfloor heating systems must be operated with an external floor temperature sensor that limits the surface temperature to a maximum of 29 °C. This protects the floor covering and ensures that the system operates in accordance with standards. Some manufacturers – especially those of vinyl or designer flooring – even specify a maximum temperature of 27 °C. These specifications should be observed and correctly stored in the thermostat.

Ideally, the sensor should be laid in a corrugated pipe so that it can be easily replaced if it fails. Alternatively, a second sensor can be installed as a spare – this makes it easy to reconnect if necessary without having to carry out any chiselling work.

Do you require assistance in selecting the appropriate heating system?

We provide detailed descriptions of all products, numerous images showing real-life applications, as well as manuals and operating instructions – all directly with the product. Our expert service team is also available at any time to offer advice and assistance. Don't hesitate to contact us now!

Deutsch

Deutsch