Would you also like to install an electric heating solution and still have questions? We are happy to help!

Professional installation: Connection of two heating mats for electric underfloor heating

Preparation of the substrate and precise installation planning

When installing electric underfloor heating, it may be necessary to connect two heating mats in parallel for larger areas in order to achieve full-surface and even heat distribution. Careful planning, the right choice of materials and professional installation are crucial for safe and efficient operation.

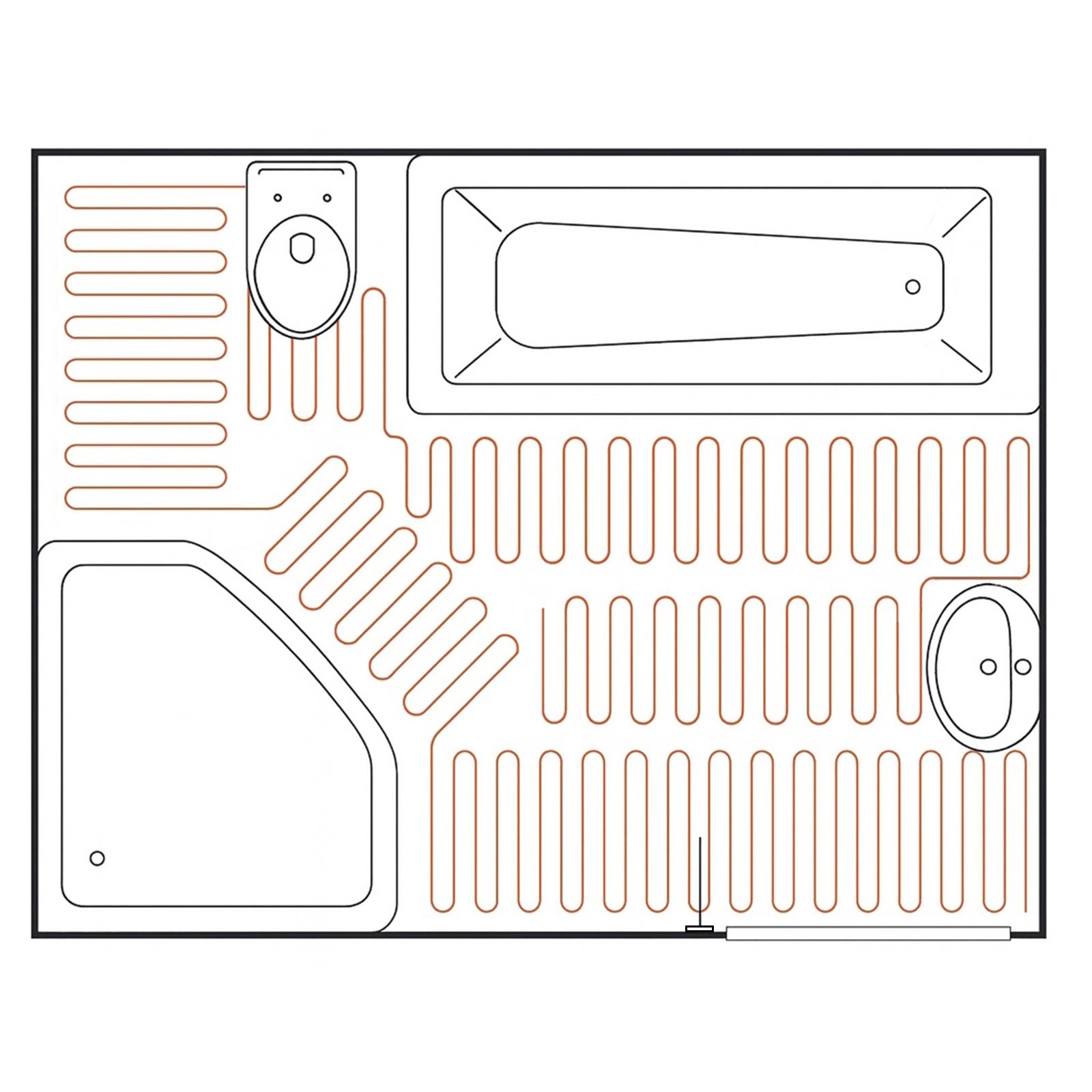

Before installation, it is advisable to draw up a detailed installation plan. This should include the positions of the heating mats, the location of the thermostat and the position of the floor temperature sensor. The accompanying installation instructions for the heating mats provide blank squared pages for this purpose, offering sufficient space for a detailed sketch. This allows the subsequent course of the heating mats to be precisely documented and traced at any time if necessary.

Next, the necessary wall slots for the power supply and sensor are created. The cables should be laid in separate corrugated pipes. On the one hand, this prevents mechanical tensile loads from being placed on the components when newly laid screed, which can still sink slightly during the drying phase. On the other hand, laying the floor temperature sensor in an corrugated pipe makes it easy to replace in the event of a defect – without having to remove the floor covering or pry up the screed.

-

Parallel connection of large areas for even and efficient heat distribution

-

Create a layout plan with the exact position of heating mats, thermostat and sensor

-

Corrugated pipe installation of power and sensor cables for protection and easy sensor replacement

Precise installation and adaptation to room layouts

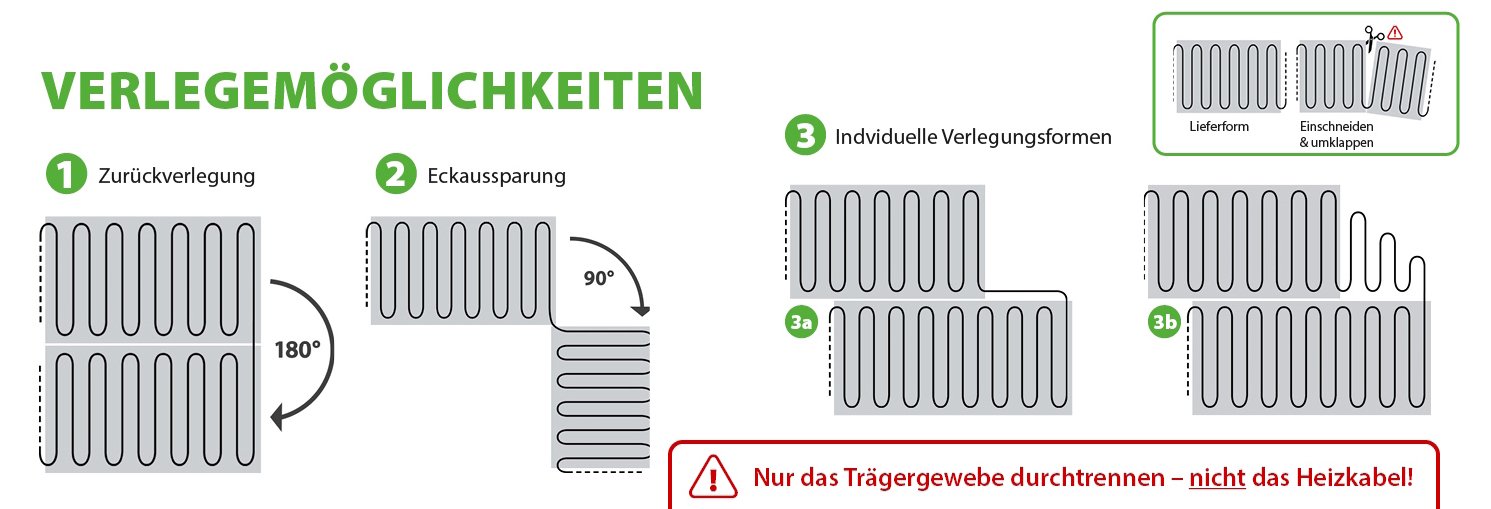

Before laying the heating mats, the substrate must be thoroughly cleaned and, if necessary, primed to ensure optimum adhesion. The heating mats have a fixed width of 50 cm, which makes planning and positioning much easier. The mats are then laid out to fit precisely in the designated area. The heating mats must not be shortened, as this changes the electrical resistance and can impair the function of the heating system.

To adapt to the room layout, the carrier fabric can be cut at a suitable point to fold the heating mats up to 180° without damaging the heating conductor. For angled surfaces, the heating wire can also be partially detached from the carrier fabric and laid flexibly along the desired course. In this way, even complex room geometries can be heated without gaps.

When laying the mats, a minimum distance of at least 5 cm from walls and at least 20 cm from heating pipes and radiators must be maintained. In addition, the heating mats must not be laid under fixed, fully supported furniture, as this can lead to heat accumulation.

-

Clean the substrate and prime if necessary

-

Cut the backing fabric to size for a perfect fit

-

Do not shorten the heating mats and maintain the minimum distances

Function and safety test with documentation in the measurement report

Before and after installing the heating mats, it is essential to check the insulation resistance and total resistance. These tests provide direct information about the functionality and integrity of the heating mats. During the measurements, the mats must not be connected to each other, but must be tested individually.

The resistance value measured at the factory is noted on the type plate of each mat and serves as a reference. All results should be documented in the test report included in the respective installation instructions. This careful inspection allows any damage to be detected and repaired at an early stage before further floor work begins.

The battery-powered Mi-Guard cable guard is particularly helpful here, as it remains connected to the heating mats throughout the entire installation process and provides both visual and audible warnings in the event of a fault.

-

Measure insulation and total resistance before and after installation

-

Compare measured values with the type plate and record them in the test report

-

Use Mi-Guard cable guard to monitor installation

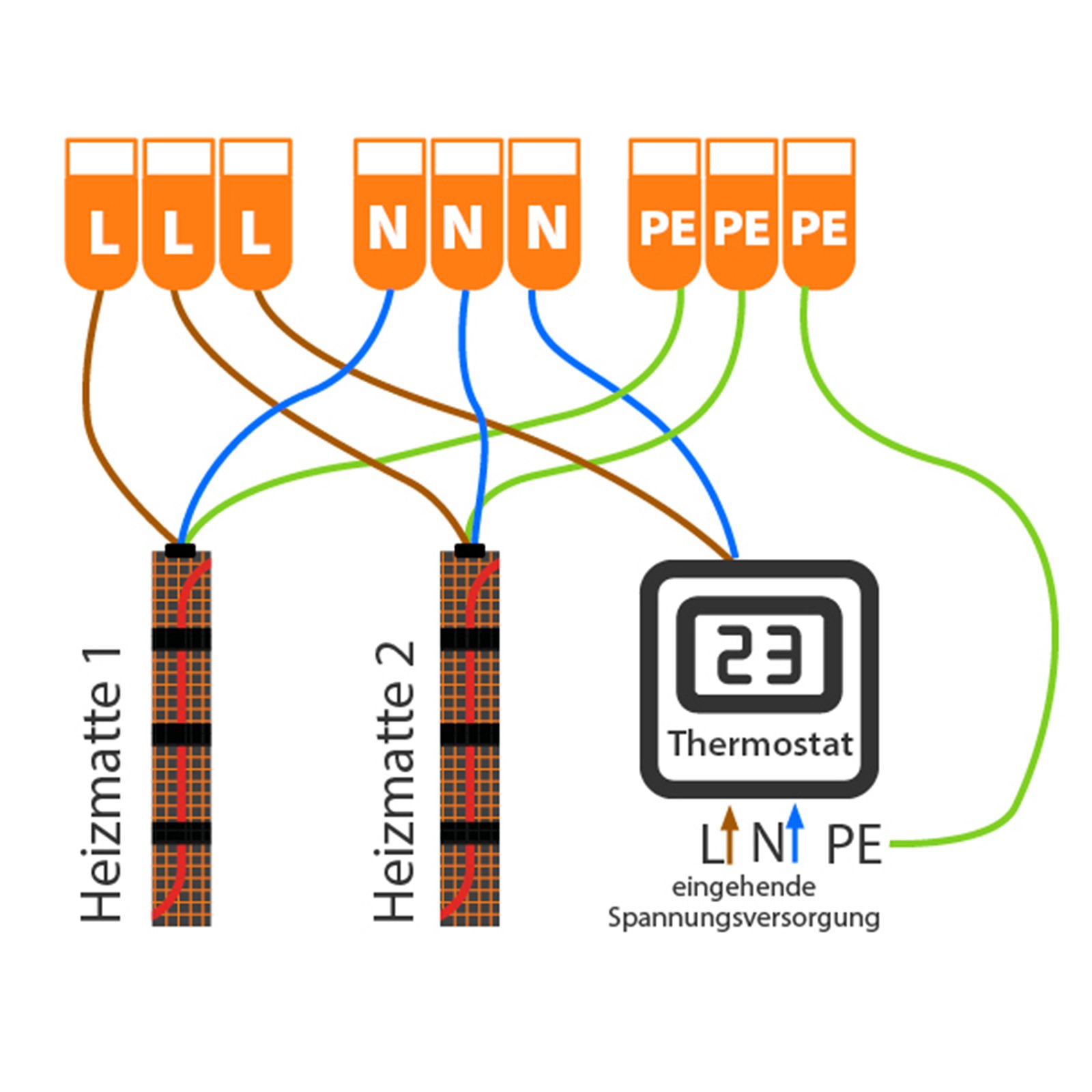

Parallel connection of two heating mats – safe connection and observance of the power limit

When connecting two heating mats, a parallel connection is essential, as this ensures that both mats are operated at the same voltage and that heating is uniform. Only identical mats with the same power rating (W/m²) should be used to avoid differences in heating behaviour or temperature. The combined total power must not exceed the maximum switching capacity of the thermostat used, which in practice is often around 3,300 watts – corresponding to around 22 m² with a heating capacity of 150 W/m².

The electrical connection is made with suitable, insulated copper cables, which are connected to the thermostat via luster terminals or WAGO terminals. The use of ferrules is recommended to prevent fraying of flexible conductors and to ensure secure contact. Connection to the mains must only be carried out by a qualified electrician in order to ensure operational safety and maintain the manufacturer's warranty.

-

Parallel connection of the heating mats ensures identical operating voltage

-

Reduce total power to a maximum of 3300 W to protect the thermostat

-

Have the installation carried out professionally by a qualified electrician

One temperature sensor is sufficient – position it correctly for accurate measurement

Even if several heating mats are installed, only a single floor temperature sensor is usually required, provided that it is positioned so that it reliably measures the actual average temperature of the heated area. The optimal position is in an area that reflects the thermal situation of the entire room as accurately as possible. The sensor itself should be located centrally between two parallel heating conductors – i.e. exactly in the centre of a heating cable loop – so that it is neither directly above a heating wire nor in an unheated space. This prevents false readings and ensures uniform, demand-based control of the underfloor heating.

-

One sensor is sufficient to measure the average temperature for the entire heating surface.

-

The optimal position for the sensor is centrally between two heating conductors of the heating mat.

-

Avoid errors and do not place the sensor directly above a heating wire or in unheated areas.

We offer everything you need for your electric underfloor heating system – with expert service that supports you from consultation to technical support.

Deutsch

Deutsch