Do you have any further questions about the thin-bed heating mat variants on offer? Feel free to contact us, we will be happy to advise you personally and work out the best variant for your project together with you.

Thin-bed heating mat - electric heating directly in the tile adhesive or levelling compound

Electric thin-bed heating systems are suitable for new buildings and renovations

The thin-bed heating system is ideal for renovations and new buildings. It is characterised by its very low installation height and can be laid quickly on the existing screed.

The heating mat is laid out and can either be laid directly into the levelling compound for various types of floor coverings such as laminate, vinyl and PVC, or into flexible adhesive for tiles.

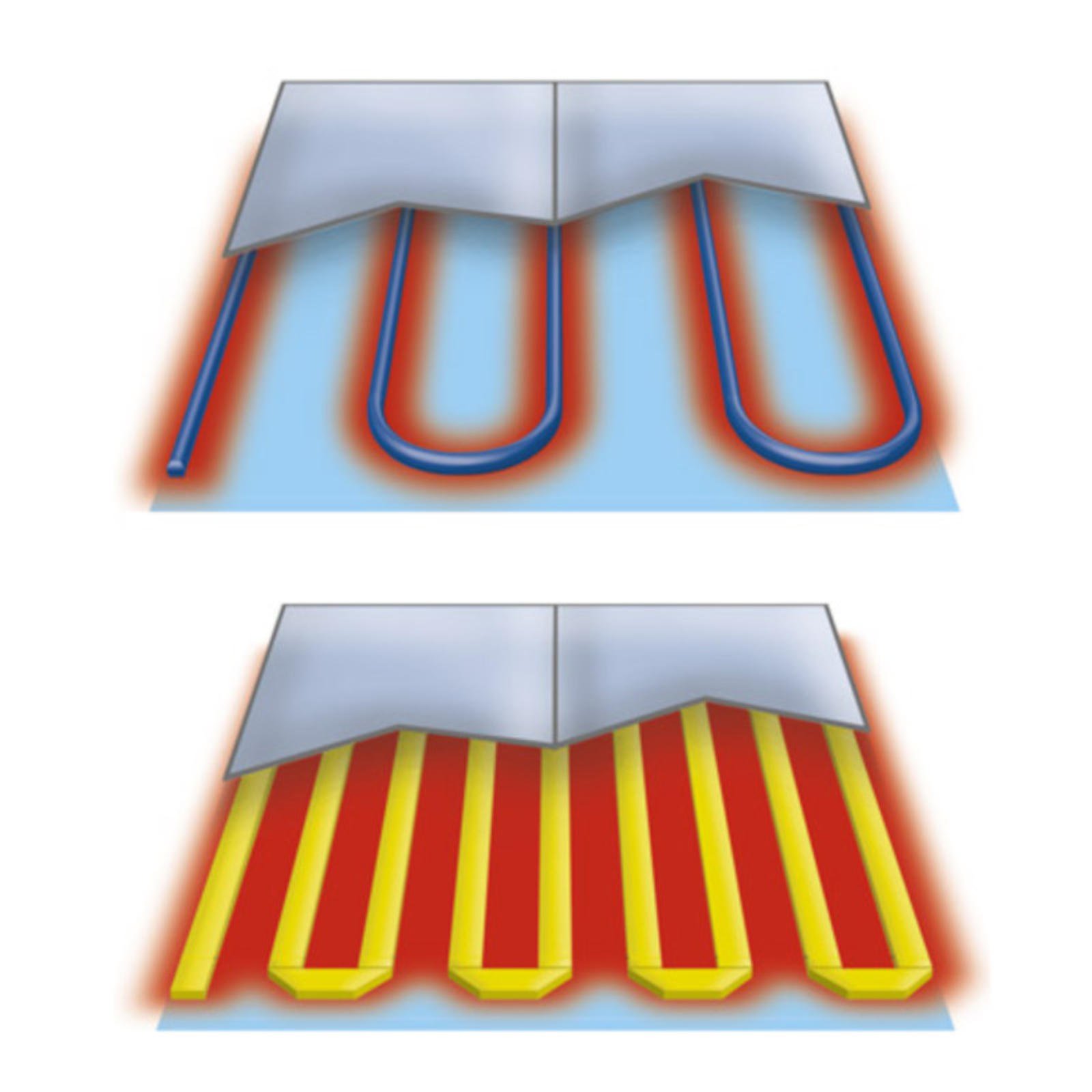

Thin-bed heating mats are available in many different versions. Older versions still had two cold connections, one at the beginning and one at the end of the thin-bed heating mat. This has been improved by the use of twin heating cables. Now the cold connection is only at one end of the mat, which makes installation much easier.

Thin bed heating mat in tile adhesive

Simple installation of the heating mats in a few minutes

Rolling out the individual lanes

All variants also have different advantages. In rooms with non-symmetrical walls, or where no or few non-square shapes are planned, such as free-standing bathtubs, round shower trays or the like, a thin-bed heating mat on a support material can be used. As a rule, these mats have a width of 50 cm and can be laid quickly by rolling them out. Once the mat has been rolled out towards the wall, the backing material can simply be cut into and the mat folded over and put back again. This way, the entire room is covered with heating in just a few minutes.

A small loop distance has a positive effect on the heating time

The loop spacing can vary, simple heating mats have a loop spacing of approx. 8-10 cm, more efficient mats come with a loop spacing of approx. 5.5-7cm. This gives more heating surface per m², which has a positive effect on heating time and effectiveness.

To achieve the highest possible efficiency, some heating mats do not use round heating conductors, but flat conductors, which further increase the heating surface per m². Another advantage of all heating mat variants is the low installation height, which is already available from a heating cable diameter of 2mm material thickness.

In rooms with many free forms, it is advisable to lay a twin heating cable from the roll, so that forms can be laid as desired to achieve the best possible heating result.

Comparison of round and flat heating cables

Deutsch

Deutsch