Stretch ceiling heating: aesthetic room design meets innovative heat source

Stretch ceilings - The alternative to drywall ceiling

Stretch ceilings are a modern and aesthetic solution for ceiling design in residential and commercial premises. They offer a variety of advantages and have become increasingly popular in recent years.

A stretch ceiling consists of a special plastic film, which is attached to the walls or ceilings with the help of profiles. The quick and dirt-free installation is a real alternative to conventional drywall ceilings. By heating the foil, it is stretched, creating a smooth and seamless surface that blends perfectly into the room design.

A great advantage of stretch ceilings is their high flexibility. They can be easily installed in rooms of any size and shape. Moreover, they can also be installed in already existing rooms without the need to remove furniture or other objects. This makes them an ideal solution for renovation projects.

Stretch ceilings also offer practical advantages. They are resistant to moisture and mold, which makes them especially suitable for bathrooms or other damp rooms. For cleaning, stretch ceilings can simply be wiped with a damp cloth, making them particularly hygienic. In addition, they can also contribute to sound insulation and thus improve the sound of the room.

Infrared ceiling heaters - Comfortable warmth with maximum efficiency

Infrared ceiling heaters are an innovative and efficient solution for heating rooms. Instead of heating the air in the room, long-wave infrared radiation with an IR wavelength of 7-14 microns (IR-C radiation) is emitted, which directly hits and heats the objects and people in the room. This creates a pleasant and uniform heat, similar to sun rays. In addition, they are particularly suitable for allergy sufferers, as they do not cause air movement or dust particles.

In connection with electric infrared heaters, it is important to know that the perceived temperature in a room is composed of the air temperature and the surface temperature of the respective objects. If the ceilings, walls and objects in a room are warm, we feel comfortable even at lower air temperatures.

Lower air temperatures are in turn associated with lower heat losses, as well as decreasing heating costs. Studies have shown that the room temperature can be around two degrees Celsius lower when infrared heating is used, without any loss of comfort. Just lowering the room temperature by only 1 °C can result in energy savings of 5-7 %.

In addition, the electrical energy used is converted into heating energy with virtually no losses, which is why this technology is considered particularly efficient. Another advantage is the even distribution of heat in the room, without creating cold or warm zones. This ensures a comfortable warmth and a pleasant room climate.

An optimal duo - stretch ceiling in combination with carbon heating film

Since both the stretch ceilings and the infrared heaters offer some significant advantages, a combination of the two systems is obvious. Due to the profile strips for fastening the stretch ceilings, there is also a certain amount of space between the actual room ceilings and the stretch ceilings. These free spaces are of course ideal for the invisible placement of the heaters.

However, classic infrared heating panels are often not suitable for installation due to their surface temperature, which is usually 85-95 °C. The required distances of often 40 cm or more to the stretch ceilings are usually not feasible or are associated with too great a loss of room height.

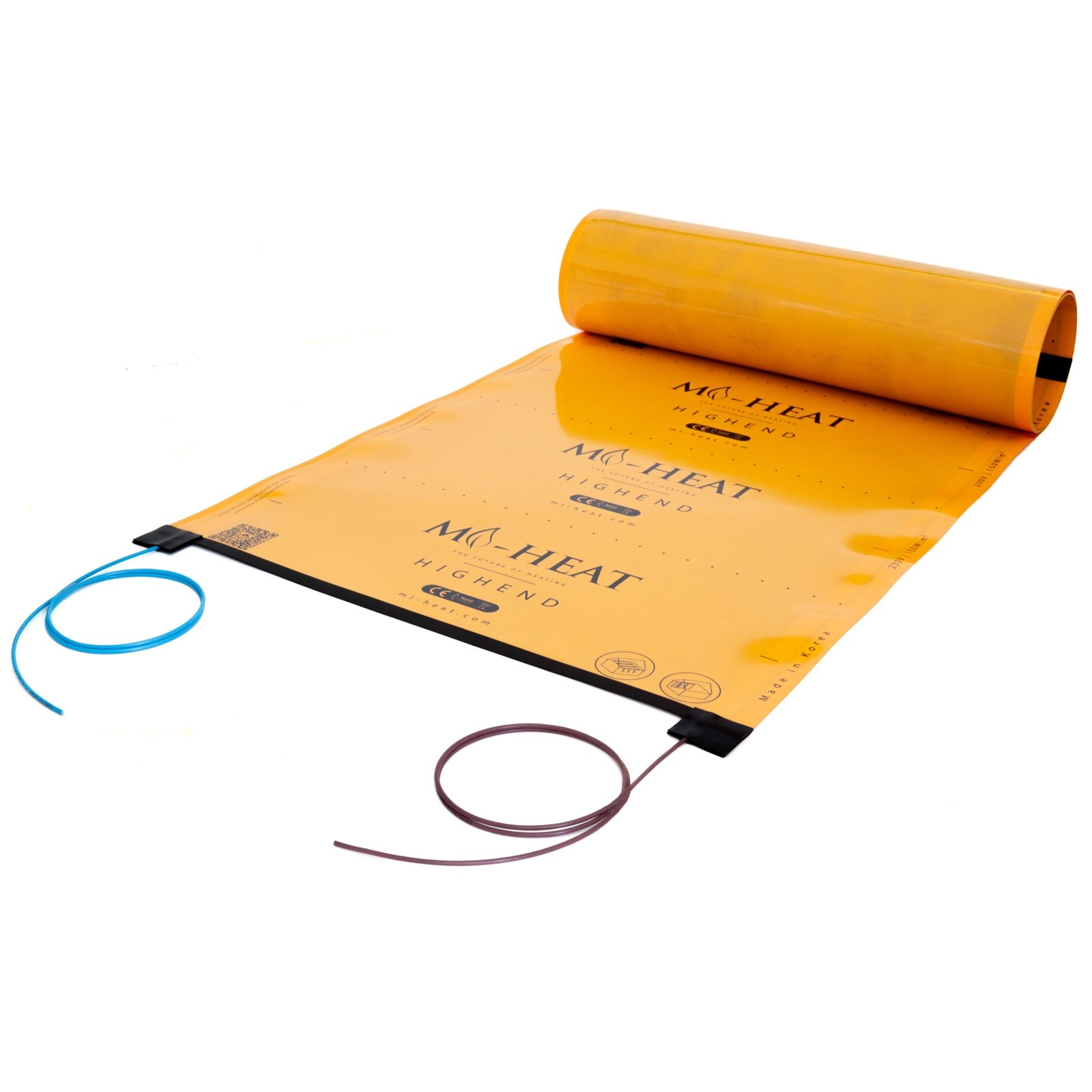

For this reason, carbon heating films are the first choice for invisible installation behind stretch ceilings. They can be installed over a large area, are particularly thin with material thicknesses of only 0.4 to 0.6 mm, and require only a small distance of approx. 3-4 cm from the stretch ceiling.

A room thermostat with an external temperature sensor ensures thermal monitoring of the carbon heating films, which should be heated to a maximum recommended temperature of 40 °C. The temperature of the carbon heating films is controlled by a thermostat. Thus, the electric panel heating behaves similarly to infrared heating, but with a lower surface temperature. As a rule, models with heating capacities between 150 and 200 watts per square meter are used.

Of course, electric panel heating with carbon heating films can also be used as the main heating system. As a rule of thumb, about 60 to 70 percent coverage of the ceiling area of a room can be calculated for this. Due to the large-scale installation, the system works with lower power, which makes the principle very efficient and comfortable.

Another advantage of electric panel heating, apart from the purely visual aspects, is the relative saving of space. This is because the heating films disappear quasi invisibly behind the wall or ceiling coverings and do not take anything away from the usable area of the premises.

Our tip: We always recommend our Mi-Heat High End heating film for wall or ceiling heating, because it has a particularly robust structure with a multilayer insulation layer and an effective heating surface of an incredible 96% per square meter.

The right structure is what matters

When installing carbon heating films on a room ceiling, a few necessary distances must be taken into account. For example, there should always be at least 10 cm distance to walls and 20 cm distance to objects such as lamps, power cables, pipelines, etc. A minimum distance of 50 cm must even be maintained from other heat sources, such as a fireplace, chimney or hot water tank.

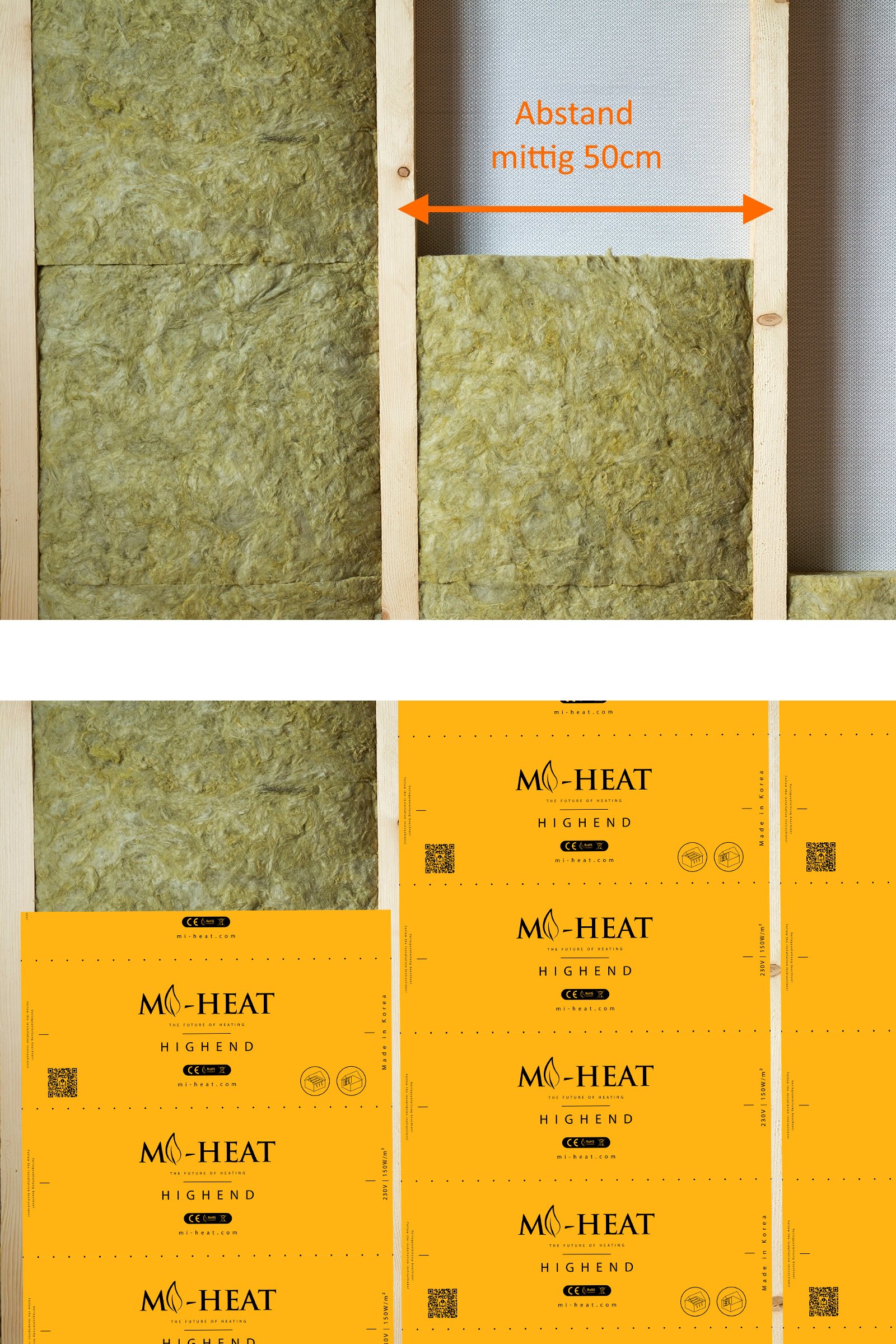

In accordance with these required minimum distances, drywall profiles or a wooden batten are first attached with a central distance of 50 cm. This distance is necessary so that the heating films can lie on and be fixed correctly. It is important that the individual heating film strips do not overlap.

The space in between should be flush with mineral wool insulation to ensure high heating efficiency and prevent heat loss. The recommended insulation thickness is 8-10 cm for a wall construction or for a ceiling construction between two storeys and at least 15 cm for the rooms under the roof.

An empty pipe for the external temperature sensor of the thermostat is led behind one of the heating films. This ensures thermal monitoring of the heating film and limits the temperature to a maximum of 40 °C, which is recommended. A central installation behind the heating film is optimal so that the temperature can be determined as correctly as possible.

The position of the thermostat should be in a freely accessible place and not be exposed to direct sunlight. If possible, a cold outside wall should also not be used for installation so that the measurement result for the room air temperature measurement is not falsified.

To fix the carbon heating films, staples (tack staples) are inserted at the outer edges on the left and right. Edge strips about 7 mm wide provide the necessary clearance for this. No fasteners, such as screws or nails, may be inserted in other areas of the heating films, otherwise there is a risk of electric shock.

Finally, at a distance of at least 3-4 cm from the heating film, the stretch ceiling is drawn into its associated profile strips and covers the complete substructure.

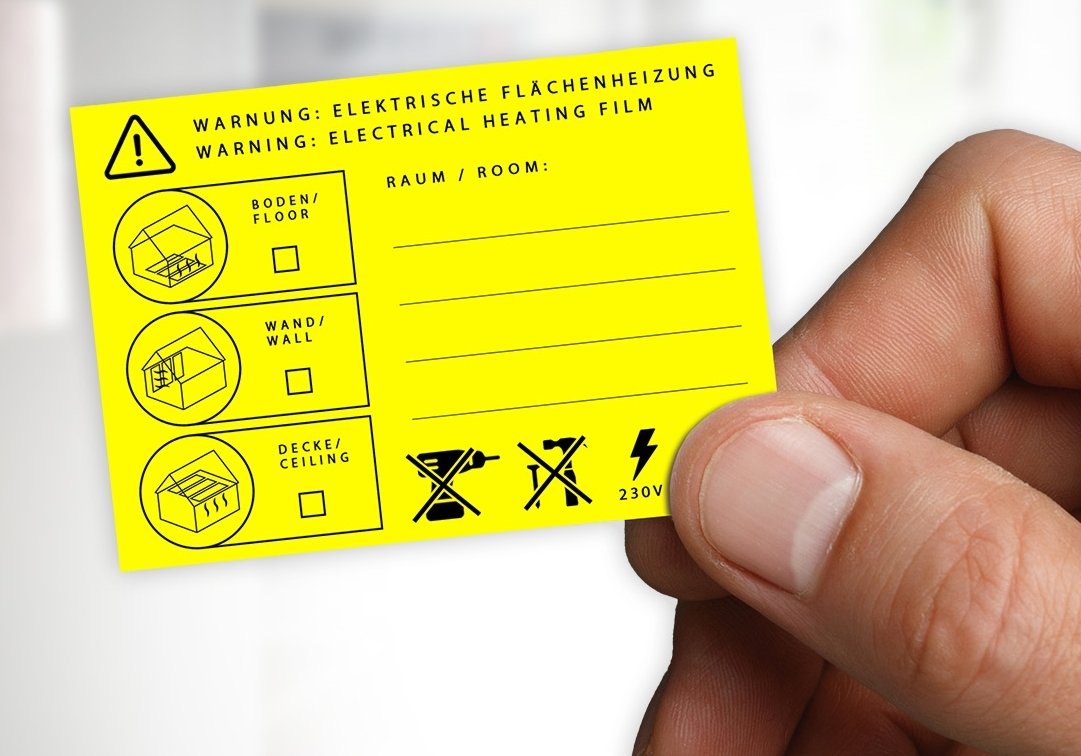

Observe compulsory labelling for electric panel heating systems

It must be taken into account that electrical panel heating systems are subject to a labelling pflicht according to the DIN EN 14337 2006-2 standard. We therefore recommend always drawing up a dimensioned sketch for each room and drawing in the exact position of the battening or drywall profile, as well as the heating films, the temperature sensor and the routing of the electrical cables.

These installation plans should be stored together with the panel heating manual in a suitable place, for example in a document holder in the control cabinet. The documents should always be accessible to persons outside the household, such as contracted tradesmen or the local energy supplier.

For this purpose, our heating films are supplied with a suitable warning sticker in signal colour, which is to be attached in the switch cabinet or the associated sub-distribution.

Recommended products:

Are you also interested in electric panel heating or are you a manufacturer or installer of stretch ceilings?

We will be happy to advise you on the various heating options and provide you with a free individual offer for your project.

Manufacturers and specialist tradesmen also benefit from our improved purchasing conditions. Become our sales partner now!

Deutsch

Deutsch